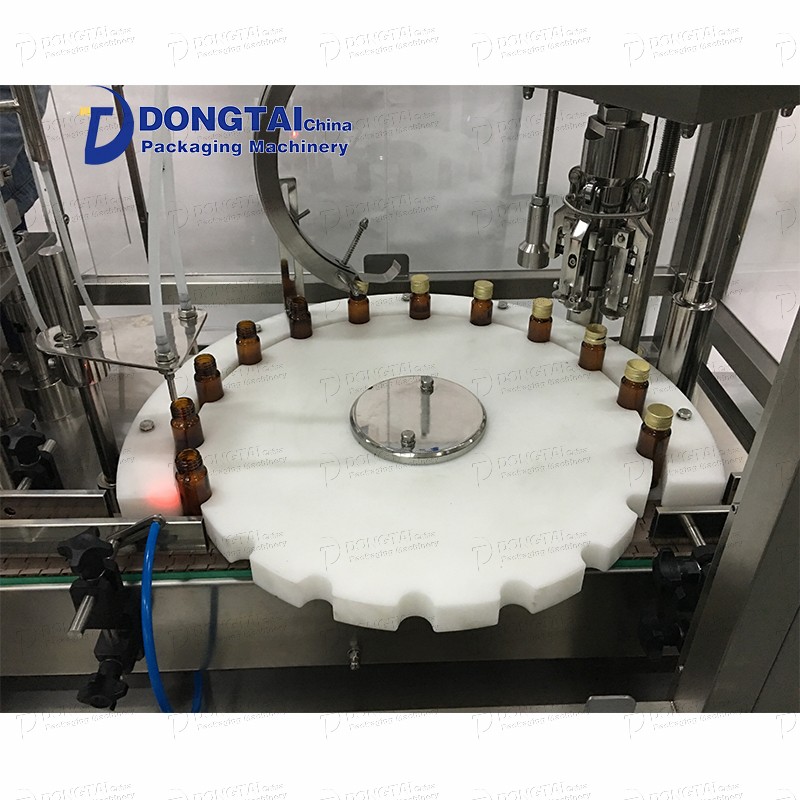

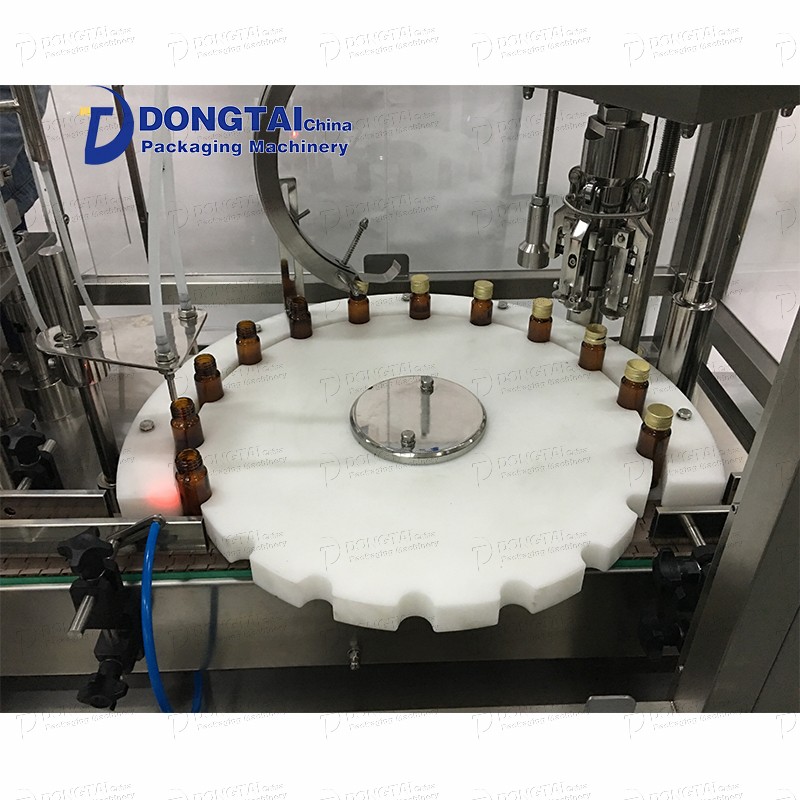

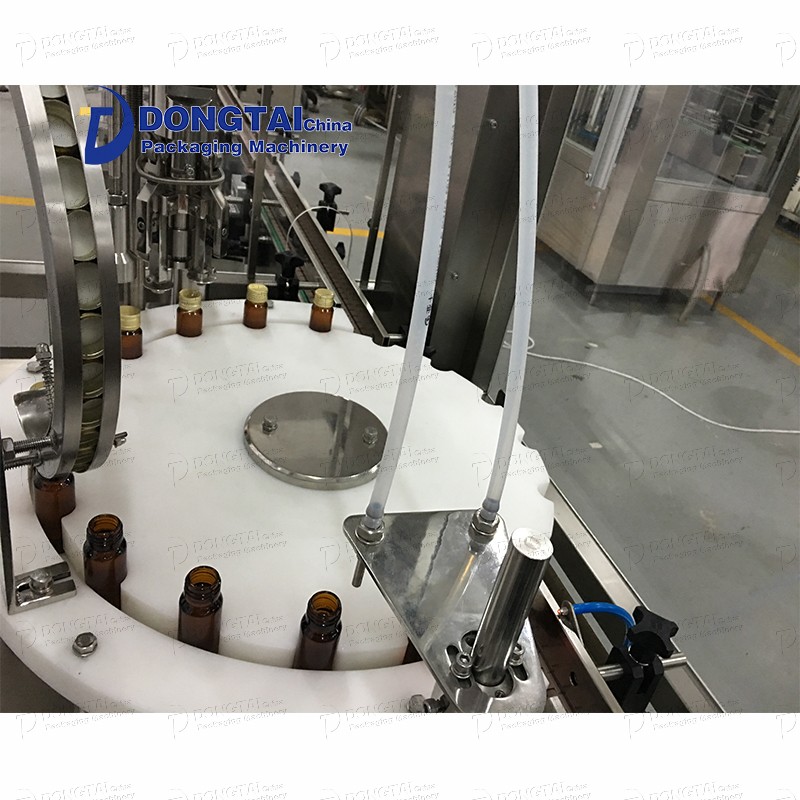

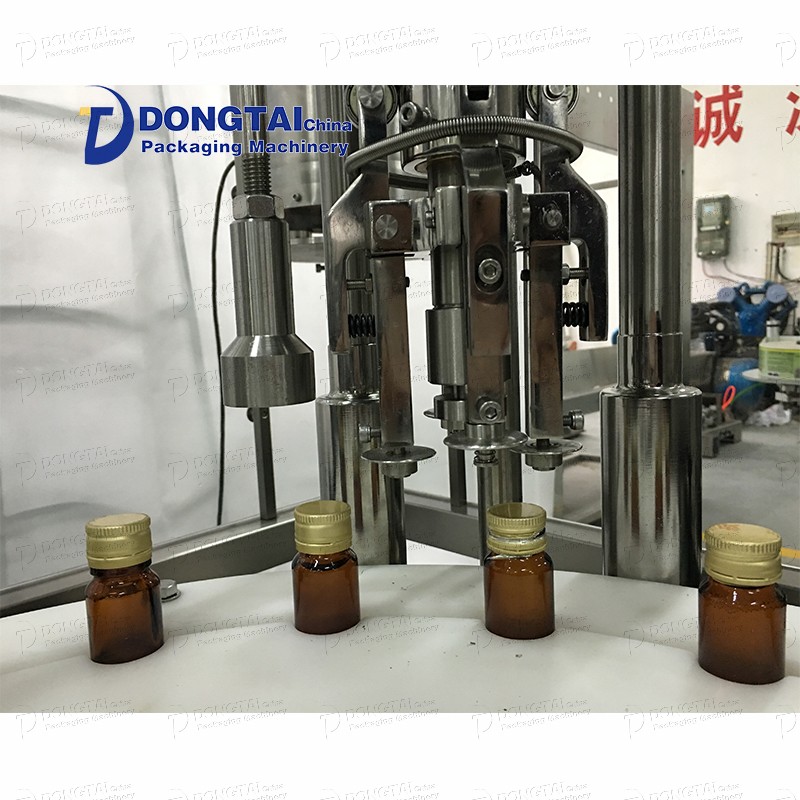

Automatic oral liquid liquid bottle filling and capping machine

- DONGTAI

- SAHNDONG

- 15 WORKING DAYS

- 1000 SETS/IYEAR

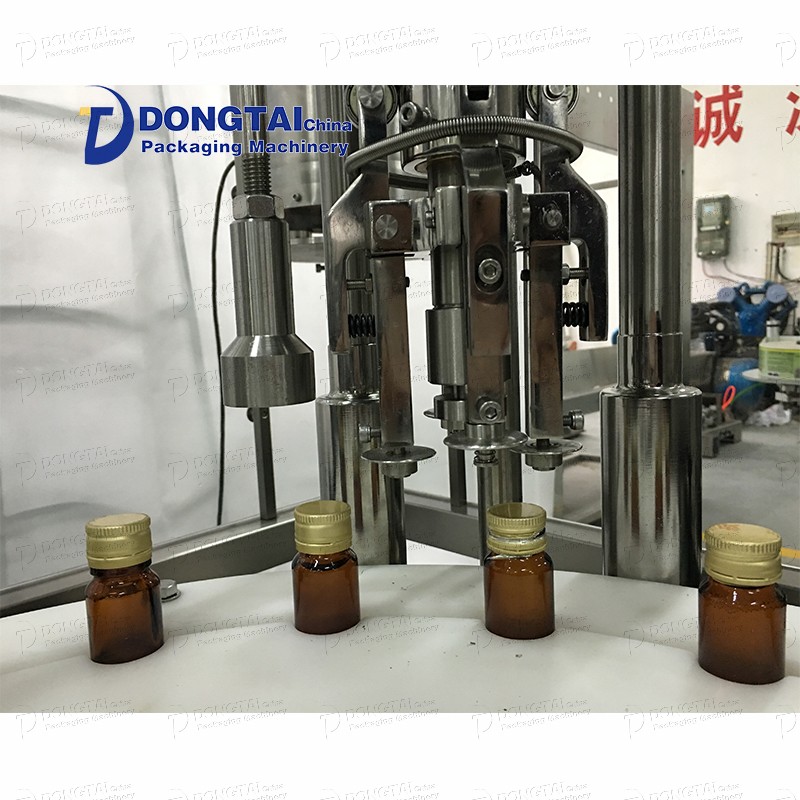

On the basis of introducing and absorbing foreign advanced technology, the oral liquid filling and capping machine is independently developed by our company, which is a professional filling and capping machine for cillin bottles, glass infusion bottles or similar bottles, which can complete the processing at the same time. Bottle, quantitative filling, capping (butyl rubber stopper), capping and capping and sealing, etc. This machine adopts high-precision closed cam indexing station imported from Japan, which has high precision, reliable operation and long service life. The indexer has a simple structure and requires no maintenance for long-term use.

Scope of application:

The oral liquid filling and capping machine is mainly suitable for filling, plugging and locking (rolling) various liquids, oral liquids and syrup liquids, honey, juice, wine, beverages, cod liver oil, olive oil, essential oils and various medical liquids. Cover, widely used in food, pharmaceutical, chemical industry and scientific research fields.

Specific advantages:

1. The oral liquid filling and capping machine has a high degree of automation, simple operation and stable operation, which can effectively save enterprise costs and improve production efficiency.

2. Each single machine can complete its work independently, with an independent operating system, and electrical components such as numerical control displays to control and adjust various parameters and display settings. Can help companies achieve standardized production

3. Each single machine is linked and separated quickly, and the adjustment is quick and simple, so that each process of production can be coordinated.

4. Each single machine can adapt to the packaging of various specifications of bottles with few adjustment parts.

4. Each single machine can adapt to the packaging of various specifications of bottles with few adjustment parts.

5. The oral liquid filling and capping machine adopts the international new technology design and conforms to the GMP standard.

6. The oral liquid filling and capping machine runs smoothly, the functions are easily combined, and the maintenance is convenient. Various production combinations can be carried out according to the user's respective product process requirements.