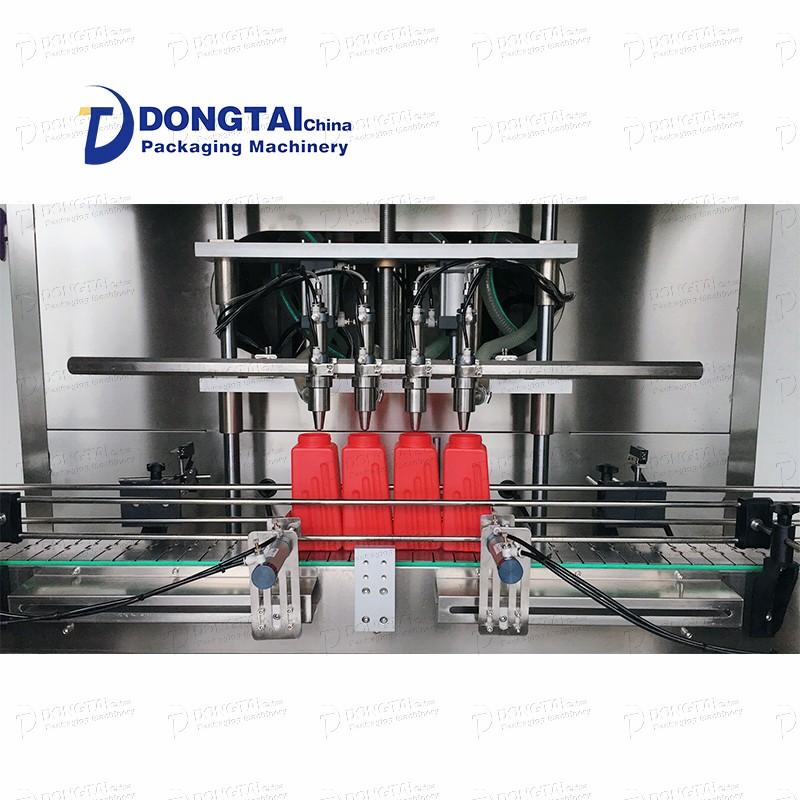

Filling machine and production line of automatic lubricant/paste/sauce/olive oil filling machine

- DONGTAI

- SAHNDONG

- 15 WORKING DAYS

- 1000 SETS/IYEAR

The automatic lubricating oil filling production line has a compact and reasonable design, beautiful appearance, convenient filling volume adjustment and high precision. Filling process control technology, color touch screen man-machine interface, one-key operation of the filling process, stable performance.

Filling machine and production line of automatic lubricant/paste/sauce/olive oil filling machine

product description:

The filling production line uses two 316 oil storage tanks to solve the problem of large filling volume. One oil inlet controls the liquid level of two oil tanks, and one oil storage tank controls 5 filling heads respectively, which is faster and more precise. It is especially suitable for quantitative filling of sauces and pastes. It is an ideal packaging machine for food, medicine, cosmetics and fine chemical industries.

Equipment advantages:

1. SUS316L anti-drip filling head: It is made of 316L stainless steel, specially designed for edible oil filling, with good passability and precise polishing inside and outside.

2. Feeding port: connect the storage tank to inject into the storage tank through the feed port by power.

3. Vacuum suction pipe: The color of the air pipe and the material pipe are distinguished, which is convenient for maintenance and replacement. Black trachea and white vacuum suck back.

3. Vacuum suction pipe: The color of the air pipe and the material pipe are distinguished, which is convenient for maintenance and replacement. Black trachea and white vacuum suck back.

4. Receiving trough: prevent materials from being spilled on the ground and troublesome cleaning during debugging or failure.

5. Electronic control module: electronic control module, all controls are controlled by software programming, easy to maintain.