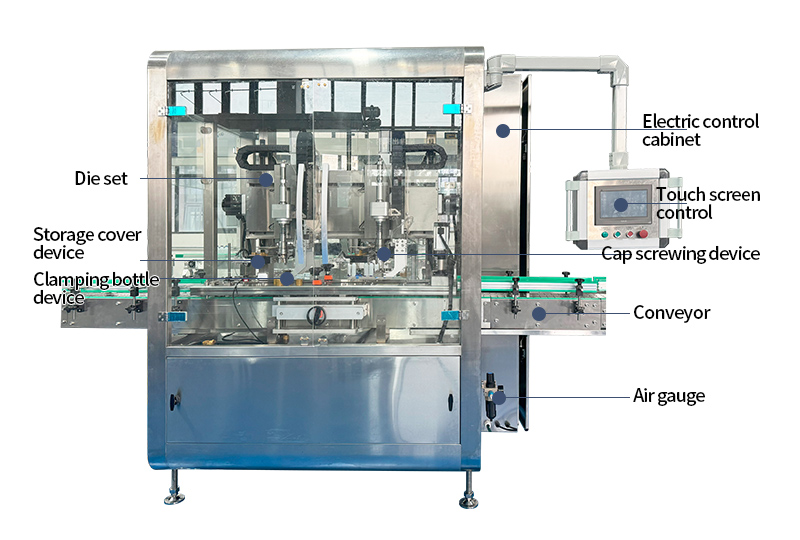

Servo Control Liquid Soap Detergent Lotion Lubricant Oil Bottle Automatic Tracking Capping Machine

- dongtaijixie

- 15

- 10

Automatic double-head servo tracking cap-attaching machine

Dual servo independent drive, real-time tracking of the conveyor belt, achieving ±1° torque accuracy and bottle cover closure without exception. Suitable for bottle heights of 20-120mm and various types of caps such as flat caps, pressure caps, and screw caps. The speed reaches 80-150 bottles per minute, and the constant torque sealing ensures zero leakage. The PLC touch screen allows for one-click parameter switching, and the bottle type switching can be completed in 3 minutes. It solves three major problems: sealing failure, low efficiency, and complex production changeover.

Automatic double-head servo tracking cap-attaching machine

Dual servo independent drive, real-time tracking of the conveyor belt, achieving ±1° torque accuracy and bottle cover closure without exception. Suitable for bottle heights of 20-120mm and various types of caps such as flat caps, pressure caps, and screw caps. The speed reaches 80-150 bottles per minute, and the constant torque sealing ensures zero leakage. The PLC touch screen allows for one-click parameter switching, and the bottle type switching can be completed in 3 minutes. It solves three major problems: sealing failure, low efficiency, and complex production changeover.

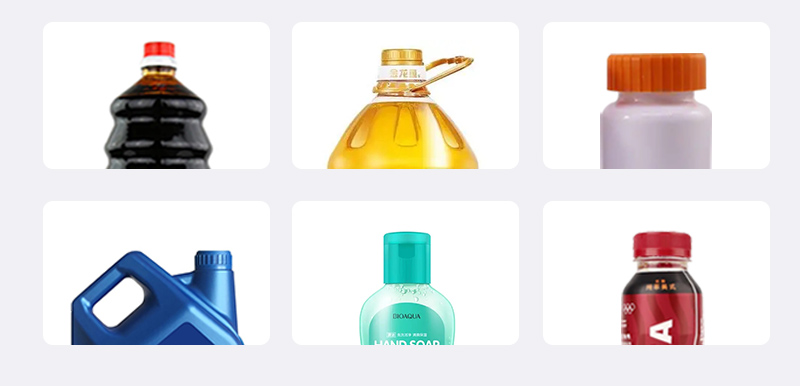

Wide range of applications

The tracking design has relatively lower requirements for the stability of the bottle, and can better adapt to various shapes of bottles (such as round, square, elliptical, and irregular-shaped bottles)

| TECHNICAL PARAMETERS | |

| Product Name | Automatic Servo Tracking Capping Machine |

Keywords | Bottle Capping Machine |

Overall dimensions | 2200 x1440 x 2300mm (L x W x H) |

Weight | 1500kg |

Applicable bottle types | Diameter: 30mm - 110mm; Height: 50mm - 250mm |

Applicable bottle caps | Height: 10mm to 35mm; Diameter: 0.18mm to 80mm |

Power Supply | 380V (three-phase four-wire) 50Hz |

Overall machine power | 7KW |

Production capacity | < 5500 bottles per hour (example: 100 mL) |

Required gas source | 0.6 MPa clean and stable gas supply |

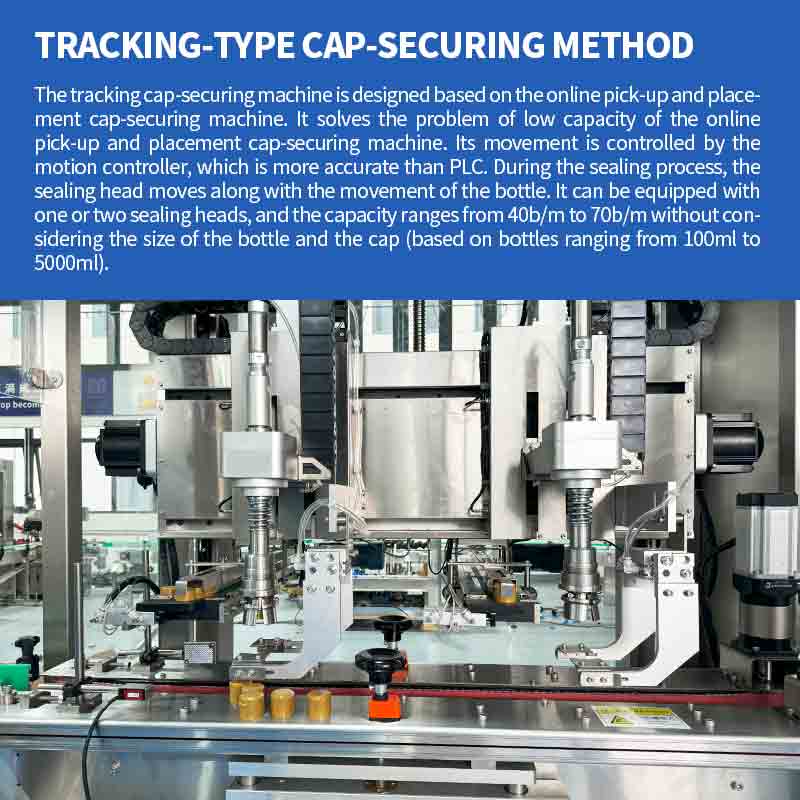

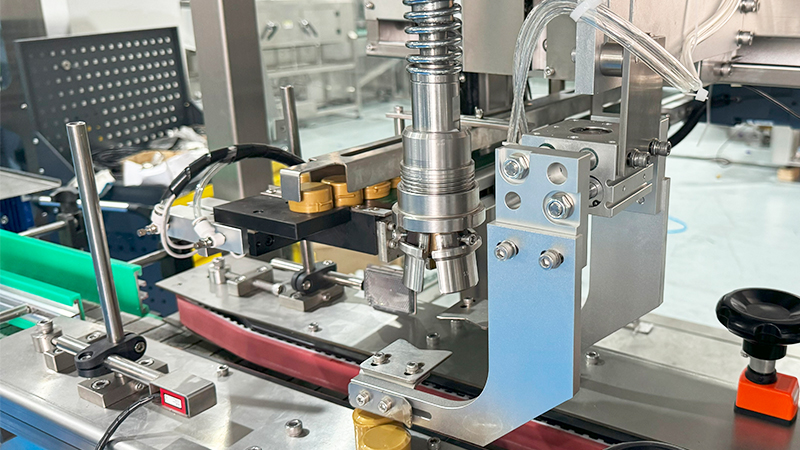

Tracking-type cap-securing method

The tracking cap-attaching machine is designed based on the online pick-up and placement cap-attaching machine. It solves the problem of low capacity of the online pick-up and placement cap-attaching machine. Its movement is controlled by the motion controller, which is more accurate than PLC. During the sealing process, the sealing head moves along with the movement of the bottle. It can be equipped with one or two sealing heads, with a capacity ranging from 40B/M to 70B/M, regardless of the size of the bottle and the cap (based on 100ML to 5000ML bottles).

Automatic lid sealing

Portable cap-rotating mechanism design

Portable cap-pressing head design. Just replace the cap head, and it can meet the production requirements for new bottles. Belt-type bottle cap. The cap insertion is stable. It can add a device for removing misaligned caps and a device for eliminating caps without aluminum foil.

、

、

The part where the bottle is held has a straight-line design.

Changing the bottle type does not require any accessories. The operation is simple and there are no vulnerable parts or potential faults.

Intelligent touchscreen control

Servo system + torque module controls the cap head, allowing the tightness of the cap to be freely adjusted.