Full Automatic Sus304 Bottle Filling Machines for Making Olive Oil cooking oil

- dongtaijixie

- china

- 15

- 10

Fully automatic twelve-head edible oil filling machine

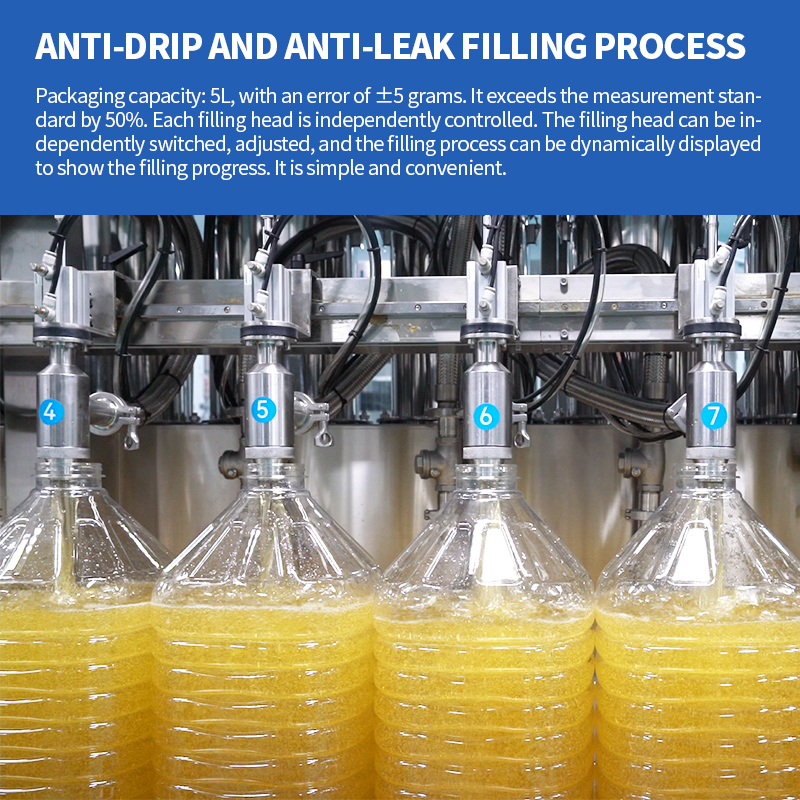

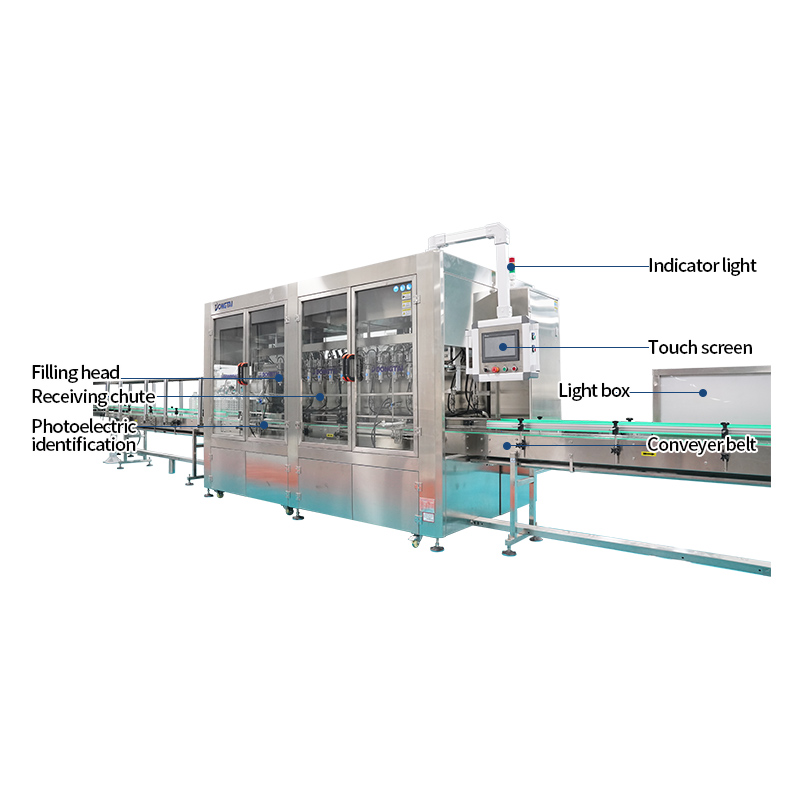

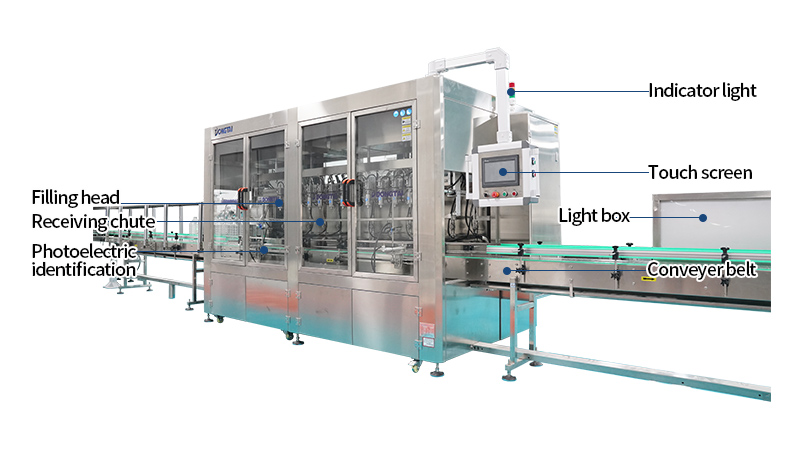

The fully automatic twelve-head edible oil filling machine is specially designed for high-speed production in large-scale oil factories. It features twelve servo-synchronized filling stations, achieving an ultra-high precision of ±0.2%, with a filling speed of 150-300 bottles per minute. The nitrogen protection system prevents oxidation, and the food-grade stainless steel channels comply with GMP/HACCP standards. The intelligent anti-drip technology is suitable for 5-2000 cP oils, and it can be switched between 8 bottle types with one click. The entire line integrates filling and capping, increasing production capacity by 300%, with a loss rate of ≤0.15%, addressing the core needs of efficiency, freshness, and compliance in large-scale production.

The fully automatic twelve-head edible oil filling machine is specially designed for high-speed production in large-scale oil factories. It features twelve servo-synchronized filling stations, achieving an ultra-high precision of ±0.2%, with a filling speed of 150-300 bottles per minute. The nitrogen protection system prevents oxidation, and the food-grade stainless steel channels comply with GMP/HACCP standards. The intelligent anti-drip technology is suitable for 5-2000 cP oils, and it can be switched between 8 bottle types with one click. The entire line integrates filling and capping, increasing production capacity by 300%, with a loss rate of ≤0.15%, addressing the core needs of efficiency, freshness, and compliance in large-scale production.

TECHNICAL PARAMETERS

| Number of filling heads | 12 |

Filling efficiency | 3000 - 3500 bottles per hour |

Quantitative error | ±2G (at 500G) |

| Working voltage | 380/220V (customizable) 50Hz |

| Working pressure | 0.6 - 0.8 MPa |

Filling capacity | 100 - 500ML, 500ML - 5L, 5L - 30L |

| Machine dimensions | 2600X1800X2300 (length x width x height in millimeters) |

Detailed Photos

Servo quantification

Impurity testing