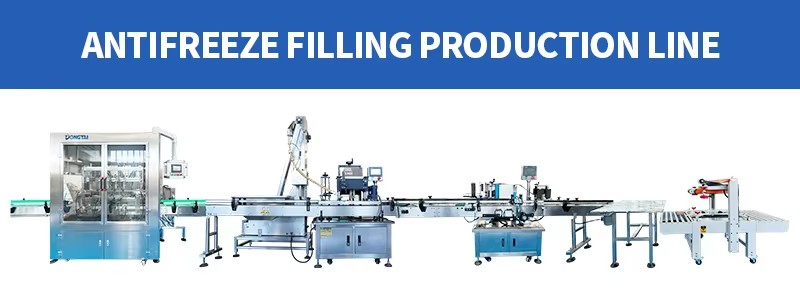

Automatic Servo Motor Piston Antifreeze Production Line

- dongtaijixie

- 15

- 10

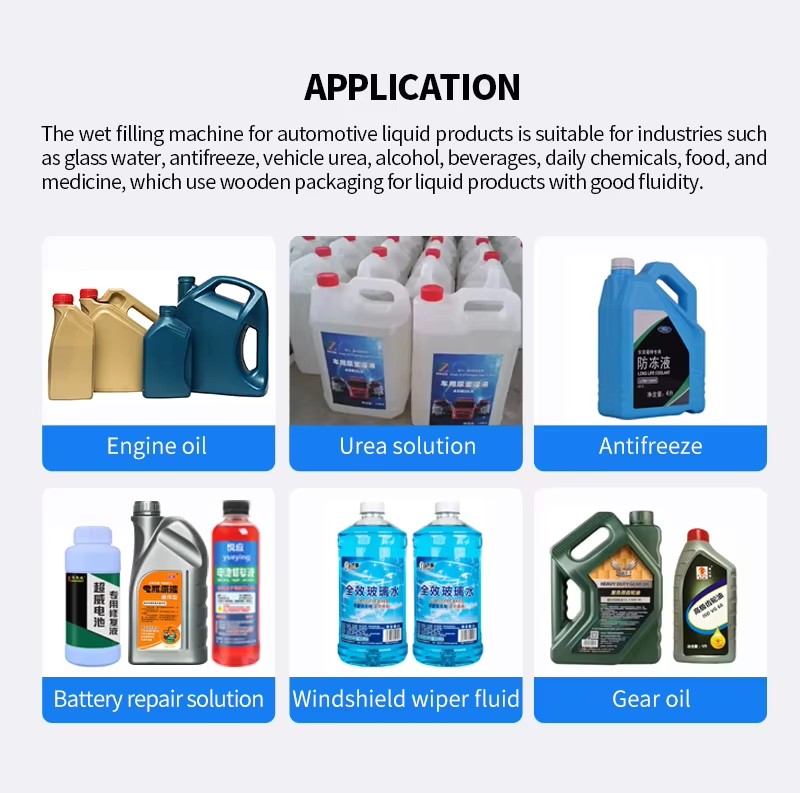

The automatic antifreeze liquid filling, screwing, labeling and marking production line is specially designed for automotive coolant and ethylene glycol solutions, integrating the entire process of bottle loading, filling, screwing, labeling and inkjet marking. The anti-corrosion material flow channels (PP/fluororubber) are resistant to acid and alkali corrosion, with a high precision of ±0.5%. The gear pump is used for filling, suitable for -40℃ low-temperature viscosity. Servo screwing + intelligent positioning labeling ensures a rate of over 99.9%, with a speed of 80-120 bottles per minute. Anti-freeze labels + explosion-proof configuration (Ex) ensure safe operation in low-temperature environments, allowing for bottle type switching in 10 minutes and addressing the three industry pain points of corrosion protection, low-temperature filling, and multi-model mixed production.

Automatic Servo Motor Piston1L 2L 4L 5L Jerrycan Antifreeze Production Line Bucket Antifreeze Coolant Filling Machine

The automatic antifreeze liquid filling, screwing, labeling and marking production line is specially designed for automotive coolant and ethylene glycol solutions, integrating the entire process of bottle loading, filling, screwing, labeling and inkjet marking. The anti-corrosion material flow channels (PP/fluororubber) are resistant to acid and alkali corrosion, with a high precision of ±0.5%. The gear pump is used for filling, suitable for -40℃ low-temperature viscosity. Servo screwing + intelligent positioning labeling ensures a rate of over 99.9%, with a speed of 80-120 bottles per minute. Anti-freeze labels + explosion-proof configuration (Ex) ensure safe operation in low-temperature environments, allowing for bottle type switching in 10 minutes and addressing the three industry pain points of corrosion protection, low-temperature filling, and multi-model mixed production.

Product Parameter

| product name | Antifreeze filling production line |

| Filling Speed | 600 - 800BPH |

| Filling Range | 500ML-5L 5L-30L |

| Working Voltage | 380/220V (Customizable) 50HZ |

| Working Pressure | 0.6 - 0.8 MPa |

| Packing specification | 900ml -4L |

| Filling Machine Dimensions | 2100X1500X2300MM(L×W×H) |

Details Images

The vacuum suction system ensures no dripping or leakage during the filling process, and it will not contaminate the conveying chain plate or the bottle body.

02/ Cap Lifter

Automatically adjust the lid direction and automatically straighten and attach the lid.

03/Sealing speed is fast

It can be adjusted according to the height of the bottle and the size of the bottle cap. The tightness can be adjusted according to the customer's requirements.

04/ Labeling is smooth and even.

The labeling is achieved through an electrical operation method using cylinders and motors. The slope angle of the structure can be adjusted, and it is applicable to various bottle types.

The automation level is high, the box sealing speed is fast, and it can reach over 20-30 boxes per minute. The tape is neatly adhered and the seal is tight.

Machine shooting in real conditions:

Fully automatic liquid filling machine

Automatic cap-securing machine

Fully automatic round bottle labeling machine

Adhesive tape box sealing machine