Automatic flow meter type edible oil filling machine

- dongtaijixie

- 15

- 10

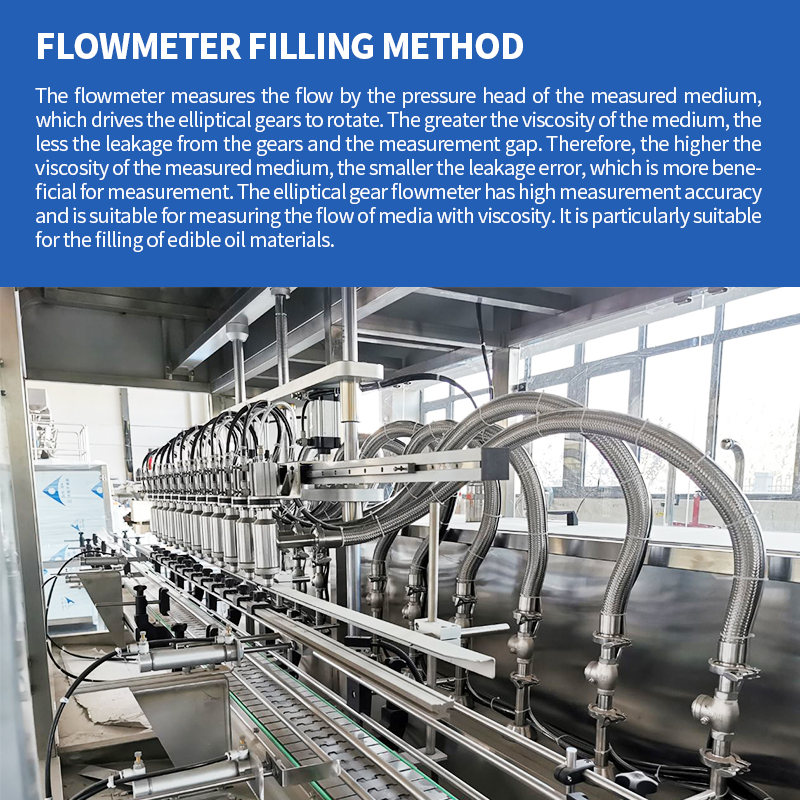

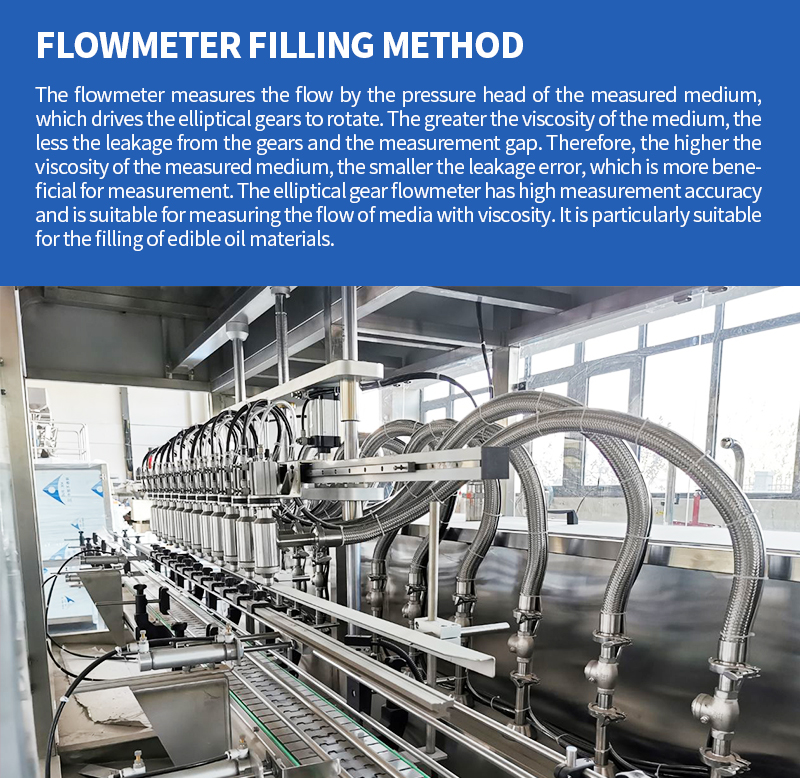

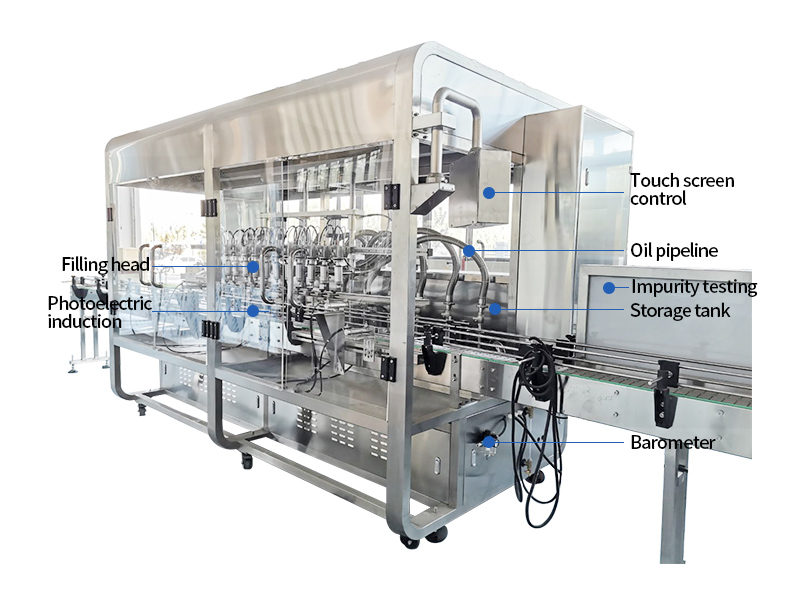

The fully automatic 12-head flow meter type edible oil filling machine is specially designed for efficient and precise filling. Equipped with 12 independent filling heads and advanced flow meter measurement technology, it ensures that the oil volume accuracy of each bottle reaches ±0.2%, significantly reducing waste. With a high degree of automation, it realizes automatic bottle feeding, positioning filling, capping (optional), and bottle discharging, and is suitable for various specifications of buckets/bottles under 5L. The dual-speed filling valve effectively prevents dripping and leakage, and the 304 stainless steel contact parts meet food hygiene standards. PLC intelligent control makes operation simple and convenient, with a production capacity of up to 2000-3000 buckets per hour. It is an ideal filling solution for medium and large oil factories, balancing efficiency and food safety.

The edible oil filling machine greatly improves the matching of filling speed and filling accuracy, and the automated filling system is easier to use and maintain. This model can be used in conjunction with a tracking capping machine, breaking the traditional linear filling machine's bag grabbing filling and truly achieving continuous bottle production on the filling line.

It can automatically adjust according to different products, and the operation is convenient. Various formulas can be saved and read in one click.

Fast and slow dual-speed filling

At the beginning of the filling process, it is filled at full speed. When it reaches the bottle mouth position, by changing the motor speed, it can alternate between fast and slow speeds, which has a very good effect in preventing bottle overflow.

Prevent leakage and dripping

The filling head is equipped with an independent vacuum return system. The grease from the filling nozzle is uniformly collected, without dripping or leaking. It features dual-speed filling, which is more stable, does not cause foaming, and ensures more accurate filling.

Photoelectric eye recognition

The automatic eye recognition feature has the function of automatically filling bottles without any errors.