Automatic powder filling production line

- dongtaijixie

- 15

- 10

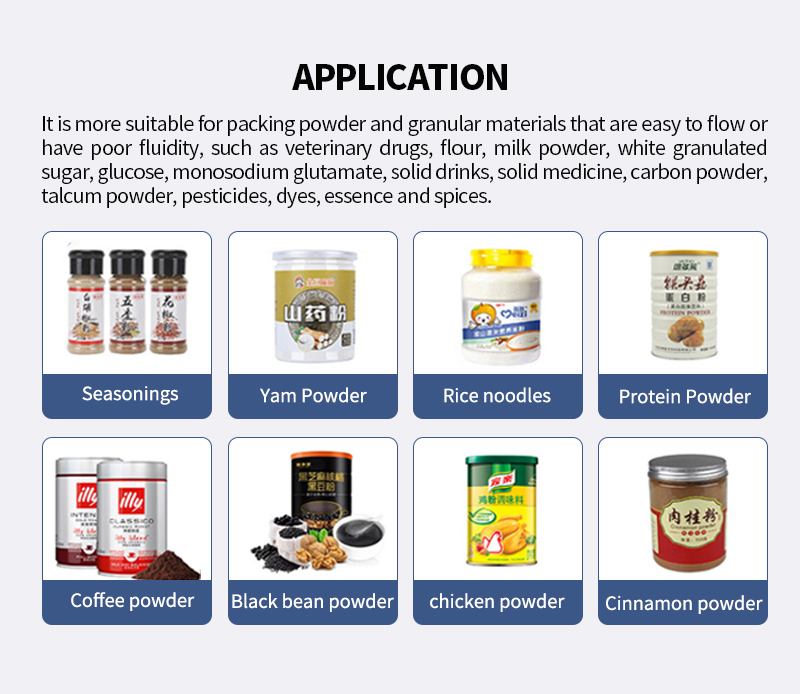

This integrated line automates high-speed, precise filling of free-flowing powders (milk powder, spices, pharmaceuticals, chemicals) into bottles, cans, jars. It typically includes container unscrambling, precision filling auger, capping/sealing, labeling, coding, and checkweighing. Engineered for hygiene (food/pharma-grade stainless steel, dust control) and accuracy (±0.5-1%), it minimizes waste and contamination. Ideal for food, nutraceutical, and chemical producers seeking high output, reduced labor costs, and consistent quality in powder packaging.

This integrated line automates high-speed, precise filling of free-flowing powders (milk powder, spices, pharmaceuticals, chemicals) into bottles, cans, jars. It typically includes container unscrambling, precision filling auger, capping/sealing, labeling, coding, and checkweighing. Engineered for hygiene (food/pharma-grade stainless steel, dust control) and accuracy (±0.5-1%), it minimizes waste and contamination. Ideal for food, nutraceutical, and chemical producers seeking high output, reduced labor costs, and consistent quality in powder packaging.

Product parameters

| Weighing range | 100 - 2000G (with adjustable screw accessory) |

| Production capacity | 20 - 35 cans/minute (depending on the materials and filling volume) |

| Number of filling heads | 2 (optional number of heads) |

| Measurement error | ±0.5% |

| Power supply voltage | 220V, 50Hz |

| Rated power | 3KW |

| Filling height | 60 - 260 MM |

Production process

The production line is customized according to user requirements. The filling section is a double-head powder filling machine, which is suitable for filling different powders. It is equipped with an eight-wheel capping machine, an aluminum foil sealing machine and a labeling machine, and has a high level of automation.

Fully automatic double-head powder filling machine

Fully automatic double-head powder filling machine - fully automatic quantitative powder filling machine. It can adjust the filling volume at will. It can be used in conjunction with production lines or used independently.

Fully automatic eight-wheel cap rolling machine

The fully automatic eight-wheel cap-lacing machine is equipped with servo motors or pneumatic control systems to precisely adjust the lacing force, ensuring that the bottle caps are both tightly sealed and do not damage the bottle mouths or the caps.

Fully automatic aluminum foil sealing machine

The fully automatic water-cooled aluminum foil sealing machine is an efficient and automated equipment that performs non-contact heating and sealing on the aluminum foil gaskets at the bottle mouths. It is used for sealing various containers such as plastic bottles, glass bottles, and composite bottles, ensuring sterility, leak-proofness, anti-counterfeiting, and preservation.

Fully automatic round bottle labeling machine

The labeling process is all automated, with simple operation and high production speed. The labeling positions are uniform, beautiful and neat. It is applicable for labeling containers in industries such as pharmaceuticals, chemicals and food.