Automatic Glass Jar Filling Machine Line Plastic Bottle Olive Oil Liquid Filling Capping and Labeling Production Line

- dongtaijixie

- 15

- 10

Automatic Olive Oil Filling Production Line

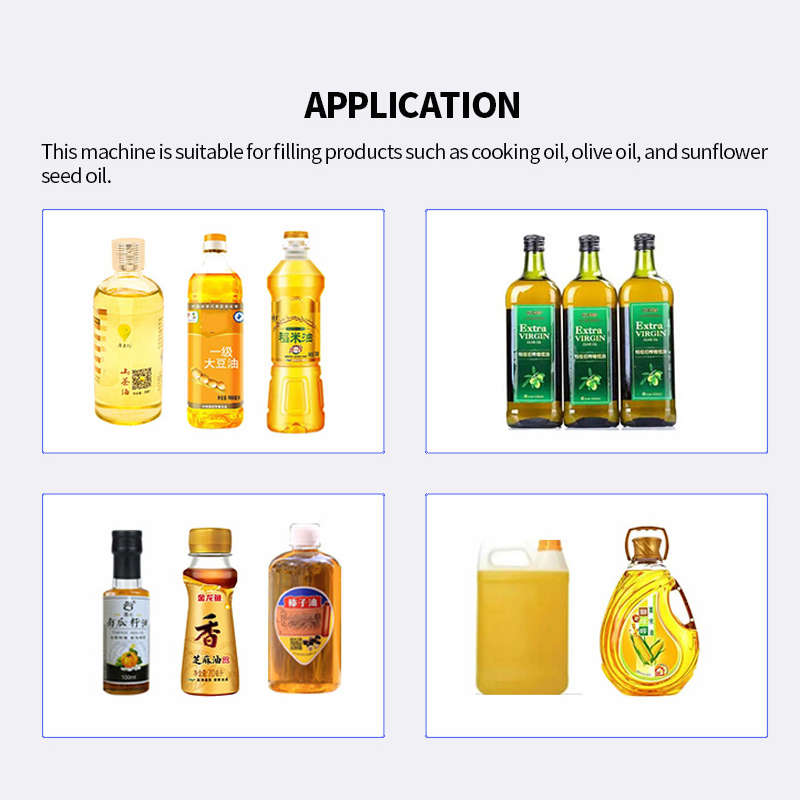

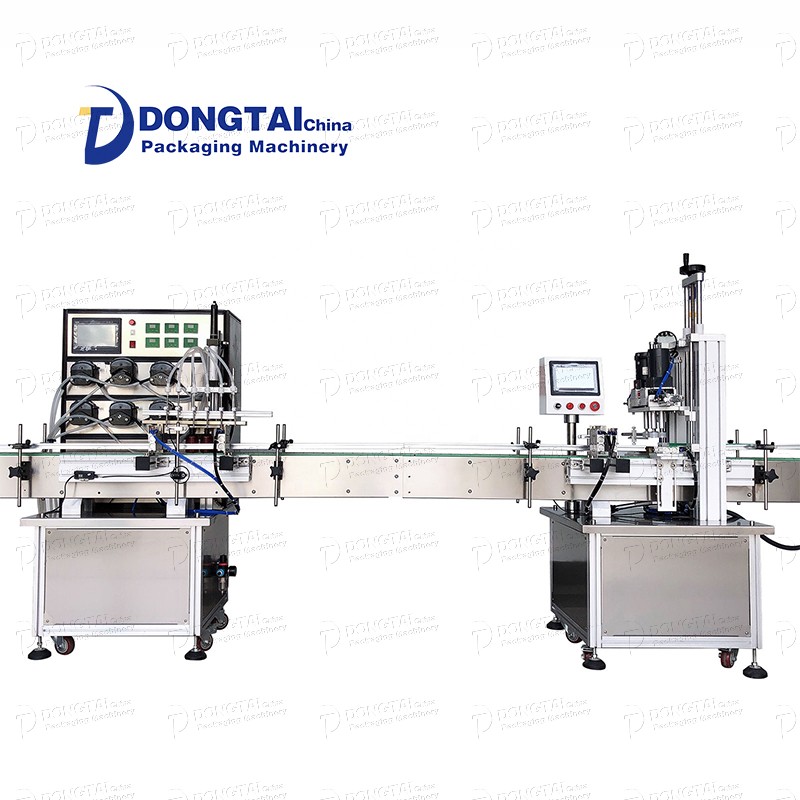

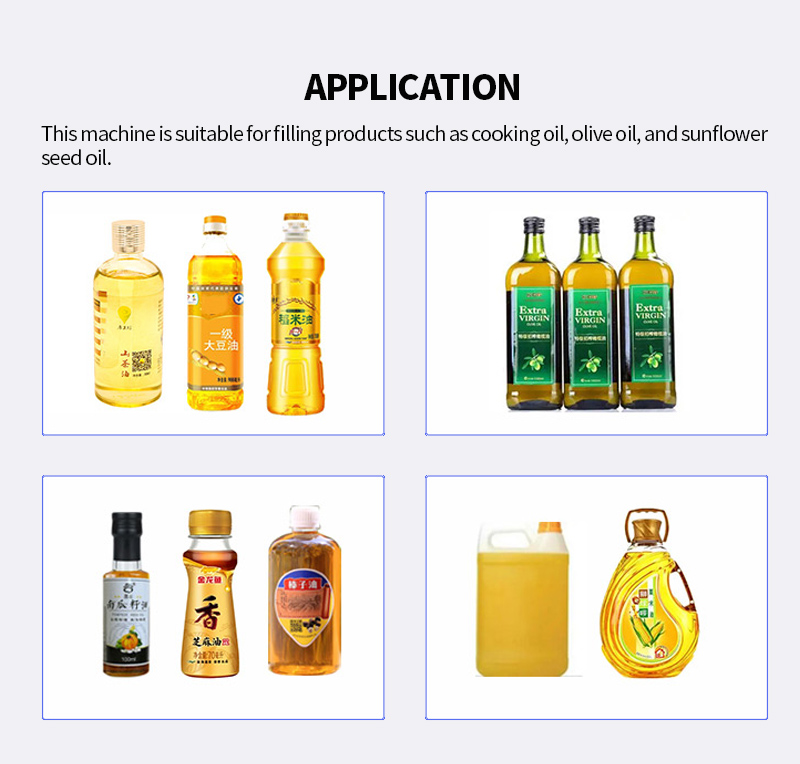

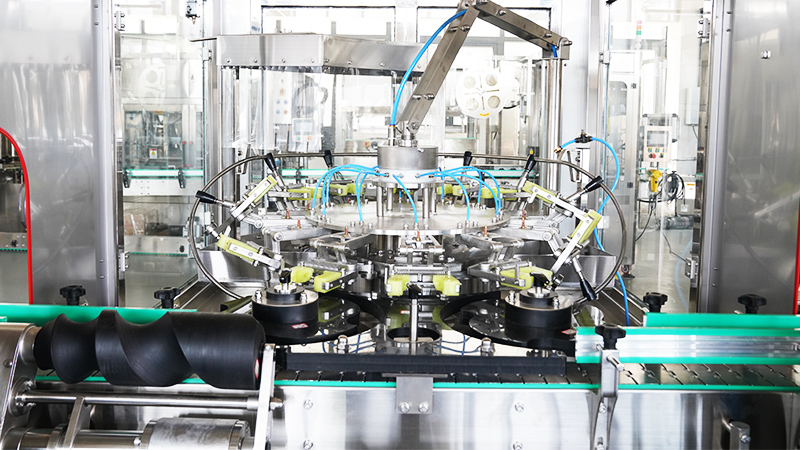

This complete, fully automatic line efficiently bottles extra virgin olive oil (EVOO), virgin, and pomace oils. It integrates key processes: bottle unscrambling, high-precision filling (piston or gravity), secure capping (screw, cork, or Doyen), induction sealing, labeling (front/back or wrap), and coding. Featuring food-grade stainless steel construction, gentle product handling to preserve quality, and easy changeover between bottle sizes. Ideal for olive oil producers and bottlers seeking maximum efficiency, reduced waste, consistent quality, and hygienic packaging for EVOO and other premium oils.

This complete, fully automatic line efficiently bottles extra virgin olive oil (EVOO), virgin, and pomace oils. It integrates key processes: bottle unscrambling, high-precision filling (piston or gravity), secure capping (screw, cork, or Doyen), induction sealing, labeling (front/back or wrap), and coding. Featuring food-grade stainless steel construction, gentle product handling to preserve quality, and easy changeover between bottle sizes. Ideal for olive oil producers and bottlers seeking maximum efficiency, reduced waste, consistent quality, and hygienic packaging for EVOO and other premium oils.

Product parameters

| Filling speed | 2500 bottles per hour |

| 8 | |

| Filling capacity | 500ML,750ML,2.6L,3L,5L |

| ±0.1% | |

| Applicable bottle height | 100 - 280 MM |

| Applicable bottle mouth diameters | 30 - 110MM |

| Main unit power | 2.5KW |

Details Images

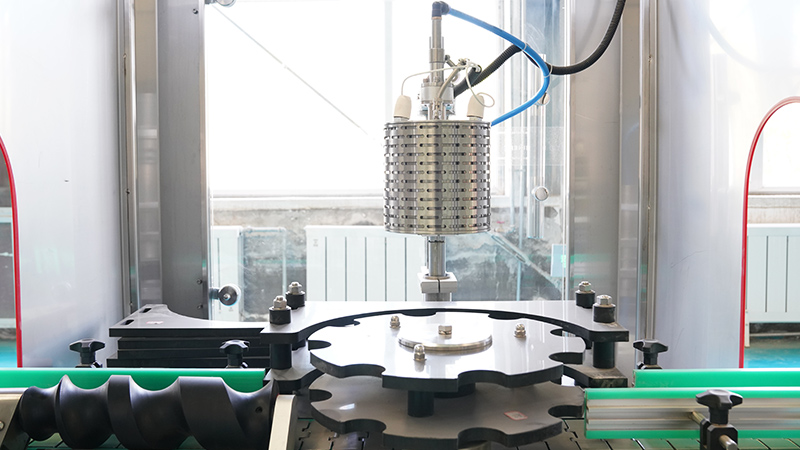

Labeling and coding

By using advanced sensors and control systems, the precise alignment of labels is ensured, avoiding errors during the labeling process. The laser coding machine is equipped with a high-speed scanner head, enabling rapid and continuous coding.

Box sealing machine

Sealing the cartons with adhesive tape is the most common method of box sealing, featuring low cost and high efficiency.